HellermanTyton Self-adhesive cable tie mounts: flexible and solid with ultra-strong cohesive strength

March 1, 2018

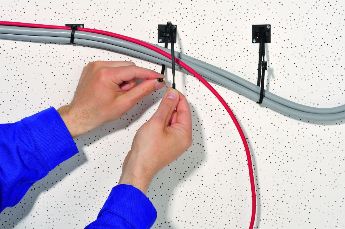

The innovative FlexTack self-adhesive cable tie mount has been developed with maximum cable routing flexibility in mind.

The flexible mounting base can be successfully applied to a variety of high- and low-energy surfaces such as

- glass

- metals (including painted, varnished or powder-coated surfaces)

- as well as plastics like polypropylene and polyethylene.

FlexTack provides a reliable fixing solution where it is impractical to use screws or bolts. The self-adhesive flexible cable tie mount

- provides greater design freedom

- offers uniform stress distribution

- as well as weight reduction and process optimisation opportunities.

A fixing element for almost any surface: flat, concave, convex or angled

The unique design of our FlexTack cable tie mount in combination with the special acrylate adhesive makes professional cable management easy even on low-energy surfaces. The installation of the cable tie mount is simple. Grasp the easy peel-off tab to remove the protective backing, position the adhesive mount on the surface, then press it down firmly for several seconds to get a good bond. Thanks to its excellent initial adhesion characteristics, bundles can be fixed immediately with a cable tie.

Advantages of the all-round self-adhesive cable tie mount

FlexTack is manufactured from heat-stabilised polyamide 6.6 (PA66HS) and is suitable for applications with an operating temperature between -40° C and +105° C. For the first time, you can affix a self-adhesive mount reliably on component surfaces subject to high temperature fluctuation.

It no longer matters whether a surface is flat, concave, convex or angled. The FlexTack self-adhesive cable tie mount FMB4APT-I (dimensions 28 x 28 x 6.3 mm; available in black or white) is the universal choice for a variety applications. It helps save time and reduce part diversity and can also help engineers reach their component weight reduction targets.

Self-adhesive cable tie mounts: flexible and solid with ultra-strong cohesive strengh

Ideal fixing solution without a drilling hole: SolidTack-Series

Standard self-adhesive cable tie mounts

HellermannTyton standard self-adhesive cable tie mounts use synthetic rubber and standard acrylic-based adhesives. They are suitable for applications where ultra-strong self-adhesive mounts, like our SolidTack and FlexTack products, are not necessarily needed.

MB- and TY-Series: quick and simple fixing

Our MB- and TY self-adhesive cable tie mounts are used to guide and bundle cables easily in conjunction with different cable ties for different bundle diameters. The mounts can be installed easily without the need for screws, rivets or drilling holes, for bolts. If a higher load is expected we recommend additionally securing the mount with screws, or trying our SolidTack-Series.

The TY-Series is smaller than the MB-Series and has a 2-way cable tie entry opposed to a 4-way cable tie entry. MB and TY cable tie mounts are suitable for applications where using screws, nuts, bolts or drilling holes to fix cables is problematic, or not the first choice.

Standard Q-Series: simply better

Standard Q-Mounts with synthetic rubber adhesive hold our Q-ties in place perfectly. The locking function makes pre-assembly easy and ensures the cable ties do not slip out in vertical mounting positions. The standard Q-Mount offers 4-way cable tie entry and is also available in a screwable version without adhesive

SolidTack-Series Q-Mounts: up to 25 % time-saving potential

Q-Mounts help unlock potential for savings in processing time and meeting weight reduction targets.

Your advantages at a glance:

Quick: there is no need for special two-component adhesives and long drying times when using our self-adhesive Q-Mounts.

Combined with the unique Q-tie, installers can benefit from up to a 25 per cent time-saving potential.

Simple: Q-mounts have a 4-way entry for Q-ties. The installation is effortless. The Q-Mount even holds the Q-tie in a vertical position, leaving the hands free to apply the cables before the tie is closed. Moreover, the Q-tie can be pre-locked for temporary cable bundling during installation.

Efficient: in combination with the special SolidTack adhesive this cable tie mount can be used on low-energy surfaces or where a standard adhesive does not bond well. The homogenous acrylate adhesive has a good initial tack.

Self-adhesive clips

Compared to the screw-fixing method, self-adhesive clips offer greater routing freedom and also reduce the risk of corrosion. HellermannTyton FKH-, RA-, RB- and SAC-Series clips are ideally suited for tool-free installation. All cable tie clips can be re-opened and reused easily when cables need to be replaced, helping you save time and money.

FKH-Series: flat ribbon cable clip

FKH clips are designed to retain the flat ribbon cables commonly used in information technology applications or in entertainment electronics or for connecting sensors. As each installation scenario is individual, FKH clips are available in different dimensions and can be supplied as self-adhesive and/or screwable versions.

RA-, RB- and SAC-Series: stick, clip and fix

RA-, RB- and SAC-Series clips do not require any additional cable tie which helps reduce overall costs and saves installation time. They can be used as a stand-alone fixing solution to guide different types of bundles.

Wires, cables, hoses or pipes – our RA- and RB-Series can fix them all. These one-piece self-adhesive clips are suitable for different bundle diameters. They can be easy installed on even surfaces once the surface has been cleaned and dried properly. The metal tab of the SAC-series can be bent to suit various bundle diameters.

They are typically used in the automotive and white goods industries.

Information and installation instructions for self-adhesive mounting bases

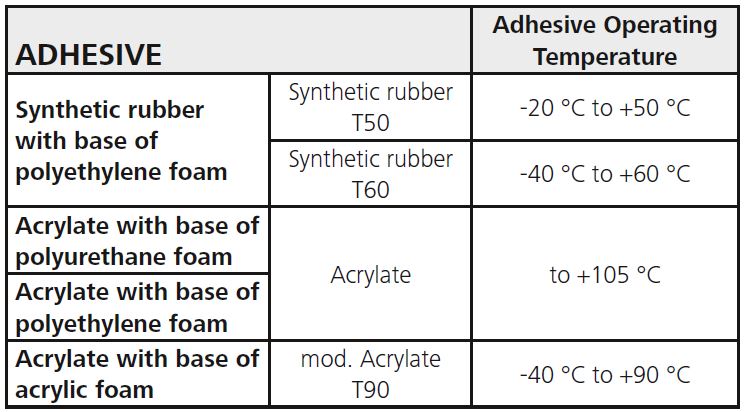

HellermannTyton self-adhesive cable tie mounts are manufactured using different acrylic-based and synthetic rubber adhesives. These allow us to meet your expectations for applications within different operating temperature ranges and expected pull-off forces.

Synthetic rubber has an excellent initial tack, allowing for almost immediate use. Acrylate adhesives generally have less initial tack, but generate a higher permanent pull-off force after they have completely bonded – usually after a number of hours.

>

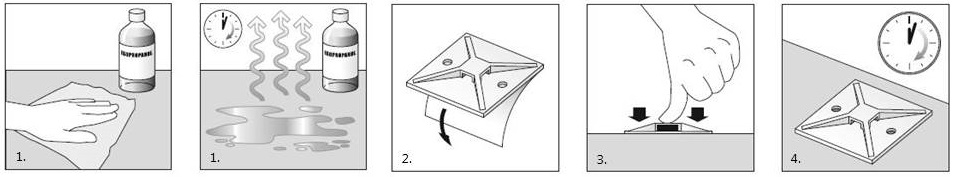

Instruction for use of self-adhesive cable tie mounts

1. The surface must be dry, free from dust, oil, oxides, parting agents and other impurities. The surface to be glued should be cleaned using a clean cloth and isopropanol/water (50/50). When using other appropriate cleaning agents, ensure that they do not attack the surface nor leave any residues. After cleaning allow the surface to air-dry completely.

2. Peel off protective backing and ensure the adhesive area is not touched.

3. Press down firmly on the base with the thumbs for several seconds.

4. Depending on the type of adhesive, wait for several minutes (synthetic rubber) or hours (acrylate) so that the adhesive can bond completely with the surface.

Advantages of our self-adhesive mounts with mod. Acrylate (SolidTack/FlexTack)

- Acrylic Foam Tape is made from a homogeneous system of high performance acrylic adhesive

- Very good initial bond

- High temperature resistance

- Adhesive offers design freedom, no need for bolts or screws

- Reduces the risk of corrosion, no need for boreholes

- Weight reduction compared to mechanical mounting

- Possibility to optimize production processes and to reduce production cost (bonding vs. screwing)

- Can compensate unevenness up to a certain degree

- Specially developed for low energy surfaces

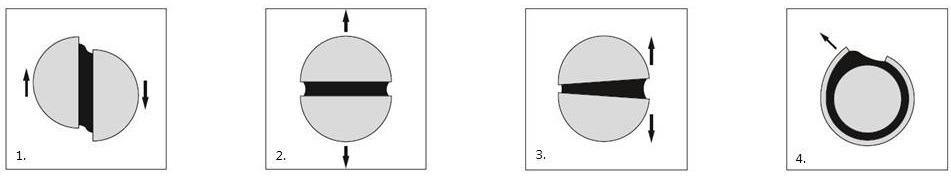

Load types on adhesive bonds

1. Shear resistance. Shear force pulls the adhesive surfaces in opposite directions along a parallel line.

2. Tensile strength. Tension force pulls surfaces apart perpendicular to the adhesive bond.

3. Cleavage resistance. Cleavage can occur where forces acting on bonded surfaces are not evenly spread but concentrated along a single line.

4. Peel adhesion. Peeling force acts on a small amount of adhesive at the edge of the tape and weakens the adhesive bond. At least one adherend is flexible.

Other cable tie mounts

Additionally to the self-adhesive cable tie mounts HellermannTyton offers a wide range of other cable tie mounts like:

Screw fixing mounts:

- MB-Series (square cut)

- Q-Mount-Series (square cut)

- MCMB-Series (detectable)

- CTAM- Series (for limited space)

- KR-Series (Curved design)

- SSPC-Series (stainless steel 316)

Harness clips for heavy duty applications for screws or threaded bolts: