Enhancing Servo System Performance and Reliability: The Critical Role of Regulated Power Supplies in Modern Control Applications

June 29, 2023

In a servo system, the choice between a regulated and unregulated power supply is crucial. It can significantly impact the performance, stability, and longevity of the system.

For servo systems, it is highly recommended to use a regulated power supply due to the following technical reasons:

Voltage Stability: Servo systems require precise control of motor position, velocity, and torque. A regulated power supply maintains a constant output voltage within a specified tolerance, typically less than 1% variation, regardless of fluctuations in input voltage or load current. This stability is essential for preventing servo motor torque and speed variations, ensuring smooth and accurate system operation.

Load Regulation: In a servo system, the load current may vary significantly due to changes in motor speed and torque, load inertia, and dynamic forces. A regulated power supply can maintain the output voltage level within the specified range even during these variations, providing consistent performance and preventing potential control loop instability.

Line Regulation: As input voltage may fluctuate due to grid disturbances or other electrical equipment in the system, a regulated power supply compensates for these variations to provide a consistent output voltage. This ensures that the servo system operates within its specified voltage range, maintaining precise control and preventing potential damage to components.

Ripple and Noise Reduction: Regulated power supplies typically exhibit lower output voltage ripple and noise compared to unregulated ones. High-frequency noise can couple into the servo system’s feedback and control signals, potentially causing jitter, reduced accuracy, and increased settling time. By using a regulated power supply, these issues can be mitigated, providing better performance and precision.

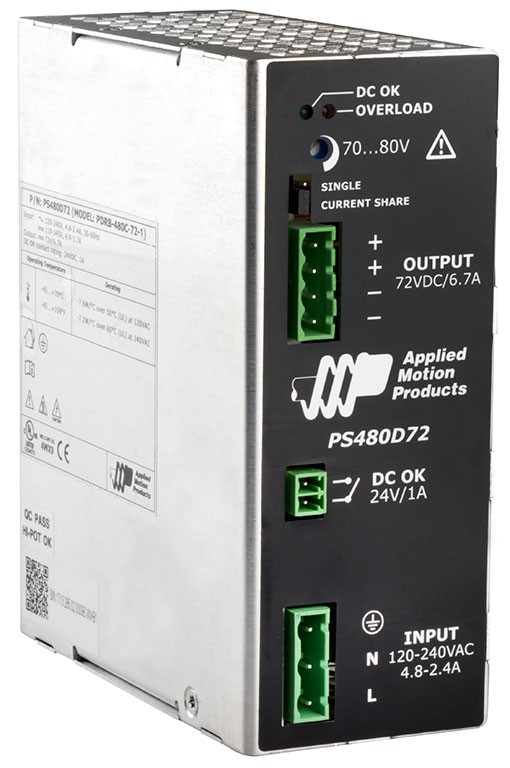

Protection Features: Regulated power supplies often include built-in protection mechanisms such as short-circuit, over-voltage, over-current, and over-temperature protection. These features help safeguard the servo system and its components from potential damage caused by electrical faults or thermal events, increasing system reliability and lifespan.

While regulated power supplies are generally recommended for servo systems due to their stability and performance benefits, there are some cases were using an unregulated power supply might be considered advantageous. Here are some reasons why someone might recommend unregulated power supplies:

Cost: Unregulated power supplies are often less expensive than their regulated counterparts. For projects with tight budgets or where the system’s performance and stability requirements are less stringent, an unregulated power supply might be chosen as a cost-saving measure.

Simplicity: Unregulated power supplies have a simpler design compared to regulated ones, which may result in fewer components, reduced complexity, and easier maintenance. This could be appealing for systems where the potential performance trade-offs are acceptable.

Size and weight: Due to their simpler design and fewer components, unregulated power supplies can be smaller and lighter than regulated ones. In applications where space and weight constraints are critical, an unregulated power supply might be an attractive option.

Efficiency: Unregulated power supplies can be more efficient than some types of regulated power supplies, especially linear regulators. Switching regulators (stabilized power supplies) generally have better efficiency than linear regulators, but in some cases, an unregulated power supply may still offer higher efficiency depending on the load and operating conditions.

Acceptable performance in specific cases: In some situations, the performance of the servo system might not be severely impacted by the voltage variations, noise, or other issues associated with unregulated power supplies. If the servo system is less sensitive to these factors or if the application can tolerate some degree of performance degradation, an unregulated power supply might be an acceptable choice.

While unregulated power supplies might be less expensive, they can introduce instability, noise, and potential risks to the servo system. For engineers designing servo systems, a regulated power supply is the preferred choice due to its ability to provide a stable, clean, and consistent voltage supply, ensuring optimal system performance, accuracy, and longevity.